ICUMSA 45 Sugar

According to the Brazilian SGS method of testing, ICUMSA 45 sugar is the highest quality sugar available on the market today. The quality of sugar is determined by a system devised by ICUMSA (International Commission For Uniform Methods Of Sugar Analysis), which is an international body that has sought to standardize the measurements which are used to describe sugar, so that no matter where the purchaser lives, or where the sugar source is located, an understanding of the type and quality of the sugar can be gained simply by quoting a rating, such as ICUMSA 45.

What Does ICUMSA 45 Actually Mean?

Sugar is tested according to a scale of whiteness. A simplistic way of looking at ICUMSA ratings is to say that the more white a sugar is, the more refined it is. ICUMSA 45 sugar is a sparkling white, highly refined sugar, suitable for human consumption and use in a wide range of food applications.

But how precisely is the whiteness of the sugar determined? In order for there to be an international standard, there needs to be a replicable scientific test to determine the ICUMSA rating of a sugar, and in order to achieve this level of precision and replicability, a colorimeter is used.

A colorimeter is a piece of equipment that determines which wavelengths of light are best absorbed by a substance. This is a useful piece of equipment, and a useful testing method because it is the ability of a substance to absorb various wavelengths of light that determines its color. Therefore, if a sugar is very white and very refined, it will absorb little light, something which can be quantified by the colorimeter.

To understand how this works in real world terms, think of how we humans perceive color. The human eye sees colors because certain objects absorb certain wavelengths of light, and reflect those which are not absorbed back to the eye. For example, a ball that appears blue to the human eye is simply made of a substance that absorbs all wavelengths of light apart from the blue ones, and reflects those back. The color, or rather the shade of white works similarly except for the fact that things which we perceive as being very white are actually absorbing almost no light, and instead are reflecting all the light back at the eye.

Sugar tested according to ICUMSA standards is usually tested with light wavelengths of 420 nm and 560 nm, and the standard colorimeter used to analyze sugar according to ICUMSA standards is a tristimulus colorimeter, an instrument which measures several readings along what is known as the visible spectrum (simply the spectrum of light that is visible to the human eye). The output reading is then based on how much light was absorbed by the sugar sample. A low reading, such as 45, indicates highly quality refined sugar which absorbs little light and appears very white to the human eye, whereas a high reading going into the 1000 + range indicates an unrefined raw sugar which absorbs much more light, and therefore appears brown and dark.

How Is ICUMSA 45 Sugar Created?

ICUMSA 45 sugar can be created from either sugar beet or sugar cane. In both cases, the product that undergoes refining is a sugary liquid, but the means of extracting this liquid varies depending on whether sugar beet or sugar cane is used. Extracting sugar juice from sugar beets is the more laborious process of the two, and involves slicing the beets thinly and then putting them into a diffuser, where they are exposed to hot water rushing over them for an hour. The sugar in the beets dissolves into the hot water, and is carried away as sugar juice.

Extraction of sugar juice from sugar cane is somewhat easier, as sugar cane contains enough water to create a juice to begin with, so sugar cane is simply crushed through rollers, and the raw juice spills out and is collected.

This raw juice can be boiled or evaporated to drive the unwanted liquid off the sugar crystals. The raw sugar which results from this process is a very deep brown color and is full of contaminants. This raw sugar can be sold to refineries as is, or it may undergo some processing to create VHP raw sugar, which is still not suitable for human consumption, but which contains fewer contaminants and has a greater sucrose concentration.

At the refinery, raw sugar is refined by a process called ‘affination’. This involves taking the raw sugar and mixing it with a syrup which is also high in sugar. The mixture is called ‘magma’, and is sent into a spinning centrifugal chamber where the liquid is spun away from the crystals, leaving just the crystals behind, minus many of the contaminants. If a refinery is working with VHP sugar, then affination may not be necessary.

In either case, the next stage is a process known as carbonization. Sugar crystals are mixed with water in a 1:1 ratio, and milk of lime (a term given to a calcium hydroxide suspension) and C02 (carbon dioxide) gas are introduced into the solution.

Three major changes are affected in the sugar solution during this carbonation process

Glucose and fructose are destroyed.

Proteins present in the sugar juice are coagulated.

The calcium carbonate created during the process absorbs the compounds which color the sugar, as well as many other microscopic contaminants.

This process can take anywhere from half an hour to an hour, depending on the amount of sugar juice being carbonized, and how refined the sugar will be when the process is finished. During the process, the calcium carbonate sinks to the bottom along with the impurities and colorants and is removed, leaving the purified sugar rich juice on the top.

The sugar juice is then taken to another tank, where is is boiled. The boiling process removes water from the juice, and creates conditions where sugar crystals begin to form. The resulting crystals are once more sent into a centrifugal chamber before being dried and prepared for sale as refined sugar.

Of course, this is a fairly simplistic explanation of the process of sugar refining, and the actual processes undertaken are significantly more involved and carefully controlled.

There are several methods of refining, which are named for the companies which developed them. The most popular methods are the Dorr method, in which refining takes place in two tanks. This is the most often used method in the United States, and the United Kingdom. Another method popular in Europe is the DDS method, which is a multistage process in which the sugar solution is filtered from contaminants after each stage.

What Isn’t ICUMSA 45 Sugar

Whilst the ICUMSA rating system is an internationally standard one, there are nevertheless some variations which can cause confusion for the sugar buyer. Generally speaking, ICUMSA 45 sugar is the term used to describe highly refined sugar, however in some European jurisdictions, the ratings system has been reversed, and one may come across European sources where ICUMSA 42 is used to describe raw, unrefined sugar. It is always best to check when contemplating a sugar purchase that the ratings system being used is the Brazilian SGS system.

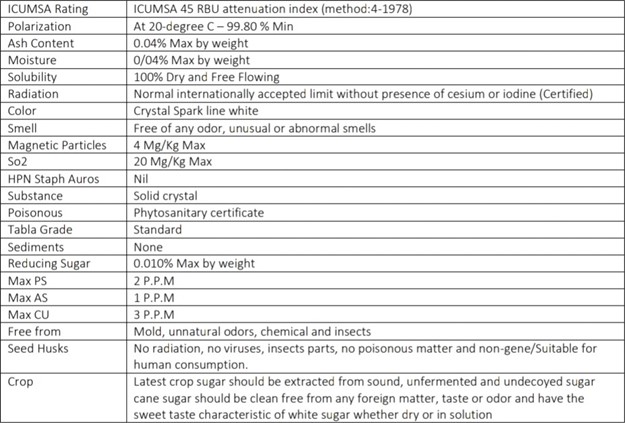

ICUMSA-45 specifications :